Dealer Locator

Over 324 dealers world wide, contact your nearest dealer

View allSince 1972 when Keith Shelbourne purchased the business assets of Reynolds Engineering Ltd and formed Shelbourne Reynolds Engineering Ltd, Shelbourne Reynolds has been designing and manufacturing farm machinery in Suffolk, England.

"We are all very proud of this remarkable achievement which is credited to the company philosophy of using the best technology available to produce technologically advanced, top quality, highly durable farm machinery. "

From two main locations

If you have questions or require advice about the, or any of our other products, then contact us today by

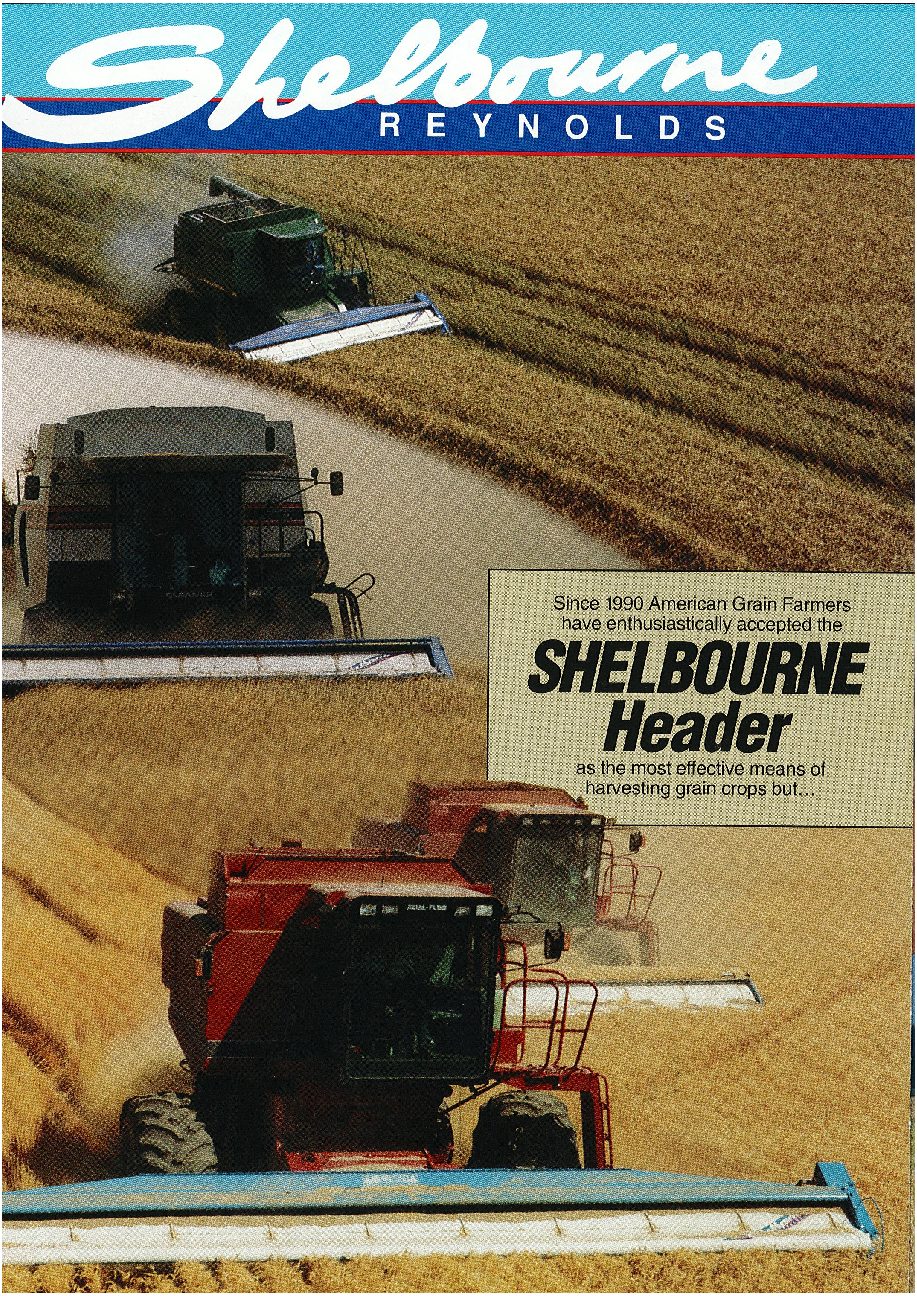

Shelbourne stripper headers were first sold in the US in 1990 in Kentucky. The concept quickly gained acceptance and sales took off. Initial sales were of 20 foot machines mostly in the Eastern states where the benefits of a fast, early harvest coupled with the benefits of planting soybeans straight back into the stripped straw were quickly recognized. machines were at the same time gaining acceptance in the rice growing states of Louisiana, Arkansas, Mississippi and Missouri. Here the benefits in terms of harvesting productivity were enormous.

The first 20 foot header sold in Kansas in 1993, was mainly as a disaster recovery tool to assist with harvest after hail storms had ripped through the wheat belt and laid large areas of crop on the ground. A 28 foot header was introduced in 1995 and once again sales surged of the wider machine as Western wheat belt farmers started to recognise the benefits of the stripped straw in their No-Till farming systems. It was at this point it was determined that a regional base was needed in order to provide parts and service advice to customers.

Keith Shelbourne purchased the business assets of Reynolds Engineering Ltd. based in bedford.

Shelbourne Reynolds Engineering Ltd was then established in Stanton, Suffolk

The company continues to build the Reynolds pea cutters, pick up reels and pick up headers for the next 10 years

SRE purchases Mather and Platt, a Manchester based self-propelled pea viner manufacturing company

Revolutionary SR9000 pea viner launched

Pea viner designs and business sold to FMC

Stripper Header design project started based on the pea viners rotary picking head

Fortschritt swather tractor units imported and sold with SRE headers and PUH’s in the UK

Stripper header launched in the UK

- Models from 10-16ft

- 100 units sold in the UK in the 1st year of production

The decision was made for the company to branch out into Livestock Equipment.

Powerspread, Fertispread and Spreadall designs purchased from Econ

The Powermix was developed using technology from the USA to design a tub feeder capable to process bales and suited for the UK market.

Powermix range of vertical diet feeders launched in the UK

CX range of stripper headers launched up to 28 feet wide. This replaced the original SR range and was the first machine that was aimed at the US prairie wheat farmer.

Parts and whole goods distribution centre opened in Colby Kansas to support the North American market.

The painting system was radically changed from a traditional wet spray to a powder coat system.

CVS range of stripper headers launched up to 32 feet wide

- Featuring the variable speed drive system

Shelbourne “home grown” hedge trimmer range launched in the UK

Parmiter shear grab, shear bucket, spring harrow, yard scraper, bale grab, post driver, disc plough and rotary slasher.

products purchased including spare parts business

Mekanag header trailer business purchased

Cubicle Bedder range launched

Powermix Pro gearbox drive range launched

A Medium Duty (MD) trimmer released to broaden the trimmer range.

Powerspread Pro range launched

To replace the Powerspread contractor

300 & 400 series farmer trimmers launched

to replace the MD series

Company 40th Anniversary

XCV range of stripper headers launched up to 42 feet wide

- Centrally Mounted

- Sprung mounted adapter plate system

25,000 square feet factory extension built.

New VFRT trimmer launched.

First variable forward reach machine with telescopic feature.

Powermix Plus range launched.

16³ - 22³

- Faster, more efficient bale chopping through

a smoother tub shape

- Lower horsepower mixing requirement

- Simpler design through incorporating the

chassis into the tub weld assembly

New 800 Series trimmers launched

- Larger pins & bushes

- Larger oil tank

- Larger oil cooler

- Integrated Toolbox

Launch of 2.8M front & rear Flail Mower

-3M overall width

Launch of the 24³ & 30³ Powermix Plus. To complete the powermix Plus range.

Launch of the XRS36 Stripper Header.

36ft / 10.8m designed to harvest rice.

With pivoting sprung loaded adapter plate & central mounting.

Heavy duty high torque step drive system.

Replacing the 700 & 800 series trimmers the new 7000 & 8000 Series was launched.

8000 Series - New S-Touch Control System

7000 Series - New look

Company 50th Anniversary

Since 1972, Keith Shelbourne formed Shelbourne Reynolds Engineering Ltd, designing and manufacturing farm machinery in Suffolk, England.

Read moreBy: Mike Lessiter

By: Shelbourne Reynolds

By: Shelbourne Reynolds

By: Shelbourne Reynolds

By: Shelbourne Reynolds

By: Shelbourne Reynolds