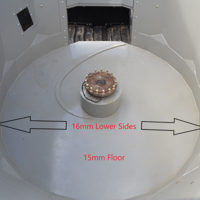

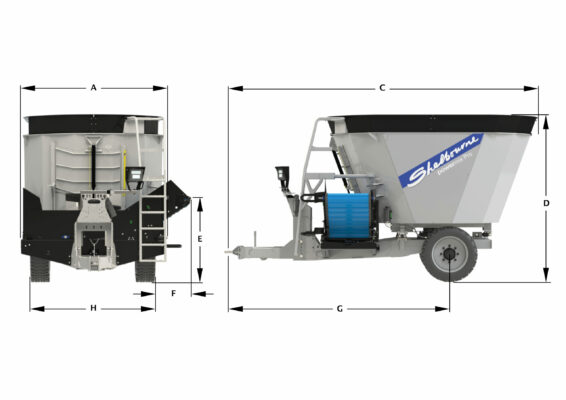

The uniquely designed central auger carries out two main functions of chopping and mixing. The Chopping function is carried out by a series of blades fixed to the auger combined with stationary blades mounted to the corners of the tub. The mixing is by the auger lifting the mixture up the centre if the tub and down the sides of the tub and continuing the cycle until the desired mix is achieved.

If you have questions or require advice about the Powermix Pro Express, or any of our other products, then contact us today.