The RSD is fitted with a fixed speed belt drive system wheras the RVS is fitted with a variable speed belt drive system.

If you have questions or require advice about the R RANGE, or any of our other products, then contact us today.

The RSD range is available from 12ft (3.6m) to 32ft (9.6m). It features a fixed frame and adapter plate system. The models are designed to suit the requirements to harvest rice.

Harvesting rice presents a unique set of challenges, high moisture, high yields and tough separation conditions. The RSD stripper header’s unique design helps rice producers gain better returns by improving harvesting performance. The benefits of using the stripper header in rice are capacity gained through increased ground speed. It is quite common to increase a combines capacity by up to 50 to 100%. This is achieved by decreasing straw intake into the combine and generally making the combine’s job easier. Productivity increases of 100% can be achieved when harvesting in adverse conditions such as down rice.

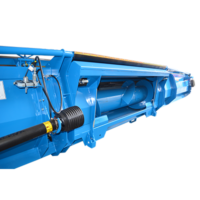

The RSD models utilize the proven High Torque Drive system, the drive transmits maximum power to the stripping rotor via a high torque timing belt. The speeds can be adjusted by swapping a combination of 3 pulleys and tensioning the belt by adjusting the pivoting gearbox which maximizes the overall belt wrap. Its overall design is simple and requires minimal maintenance.

The speed of the rotor and the auger are displayed on the monitor in cab which includes an alarm system to aid the operator.

| High torque timing belt |

| 4 fixed speeds ** |

| Speed range 400-800rpm ** |

| 3 pulleys 56t (10"), 64t (11.5") & 72t (13") |

| Sprung pivoting gearbox for belt tension |

| Minimal maintenance |

| In cab monitor & alarm system |

| ** may vary with combine spec |

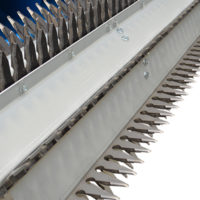

8 Rows of stripping fingers are arranged on the rearwards rotating rotor. The RSD models are fitted in the cup down (non-aggressive) position for crops such as rice or grass seed. However they can be fitted in the cup up (aggressive) positon if required to harvest alternative crops such as hard threshing dryland wheat.

The RSD drive transmits maximum power to the stripping rotor via a high torque timing belt. The speeds can be adjusted by swapping a combination of 3 pulleys and tensioning the belt by adjusting the pivoting gearbox which maximizes the overall belt wrap. Its overall design is simple and requires minimal maintenance.

The speed of the rotor and the auger are displayed and include an alarm system to aid the operator.

This is adjusted up and down using the combines reel lift and lower control and is used to control the stripping rotor intake in different height standing and lodged crops.

Stainless steel is used in high wear areas to give greater longevity.

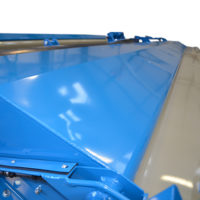

The top hood serves two purposes, firstly it seals the area above the auger to prevent any grain or dust escaping. The underside of the top hood acts as a deflector, taking the crops stream from the underside of the adjustable crop deflector and directing it into the bottom of the auger trough.

Stainless steel is used in high wear areas to give greater longevity.

The auger operates at a fixed speed between 180rpm and 200rpm depending upon the combine output speed, it is driven via a mechanical slip clutch. The auger is fitted with specially shaped centre mounted spiral paddles, these feed the grain rearwards into the feederhouse from the header. Hardox steel is used on the auger flights in the centre area to give greater longevity

The RSD range incorporates a fixed adapter plate system than can be used to adjust fore and aft header pitch. Adapters are available for, JD, Claas, Case, NH and Agco combines.

The RSD is fitted with a fixed speed belt drive system wheras the RVS is fitted with a variable speed belt drive system.

Harvesting Efficiency

The use of a RSD stripper header increases the capacity of the combine by an average of 50%.

Read more

Harvesting Efficiency

The use of a RSD stripper header increases the capacity of the combine by an average of 50%.

Read more

Crop Recovery

The RSD header has developed a reputation for improved crop recovery in lodged crop conditions.

Read more

Crop Recovery

The RSD header has developed a reputation for improved crop recovery in lodged crop conditions.

Read more

Fuel saving

Combines use considerable power to first thresh then separate grain from straw and then chop the straw.

Read more

Fuel saving

Combines use considerable power to first thresh then separate grain from straw and then chop the straw.

Read more

Improved Milling Grade in Rice

Improved milling grades are common with the use of a stripper header because the header does the majority of the threshing and the combine settings can be less aggressive.

Read more

Improved Milling Grade in Rice

Improved milling grades are common with the use of a stripper header because the header does the majority of the threshing and the combine settings can be less aggressive.

Read more

Simple, Durable Construction

Because of the aggressive nature of rice the RSD range is constructed in a way to offer greater protection against wear in critical areas by the use of materials such as stainless steel.

Read more

Simple, Durable Construction

Because of the aggressive nature of rice the RSD range is constructed in a way to offer greater protection against wear in critical areas by the use of materials such as stainless steel.

Read more

If you have questions or require advice about the R RANGE, or any of our other products, then contact us today.

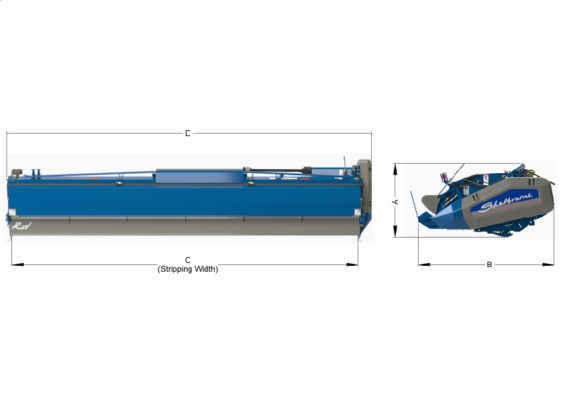

| Model | A | B | C | D | Weight |

|---|---|---|---|---|---|

| RSD 12 | 1152mm 3'9" | 2260mm 7'5" | 3600mm 11'10" | 4036mm 13'3" | 1600kg 3530lbs |

| RSD 16 | 1152mm 3'9" | 2260mm 7'5" | 4800mm 15'9" | 5236mm 17'2" | 1850kg 4080lbs |

| RSD 20 | 1152mm 3'9" | 2260mm 7'5" | 6000mm 19'8" | 6436mm 21'2" | 2100kg 4630lbs |

| RSD 24 | 1152mm 3'9" | 2260mm 7'5" | 7200mm 23'7" | 7636mm 25'1" | 2350kg 5580lbs |

| RSD 28 | 1152mm 3'9" | 2260mm 7'5" | 8400mm 27'7" | 8836mm 29' | 2930kg 6460lbs |

| RSD 32 | 1152mm 3'9" | 2260mm 7'5" | 9600mm 31'6" | 10036mm 32'11" | 3080kg 6790lbs |

Looking for something specific?

Search our support area for individual model set-up guides and more...

The auger is fitted with a slip clutch, this can slip if an excessive amount of straw is picked up at too high a ground speed.

The rotation of the rotor very successfully harvests crops lying on the ground because it has a picking up action.

Not really, the stripper head works by a rotary mechanical action rather than air flow.

No, the rotary action of the header is very gentle on the grain making the Shelbourne header popular with seed growers. The fact that most of the threshing is done in the header means that the threshing system of the combine can be slowed down to avoid grain damage, worst case scenario is over ripe soft wheat.

With combine engine speed at idle, engage the header drive and then the combine separator, causing the combine separator and the header to engage at the same time, reducing the snatch in the header drive line.

Please Click Here to download a document to explain an easy way to understanding your serial number. It is important to quote this number when ordering parts.

The CVS and XCV range of headers are equipped with a variable speed belt drive system enabling the operator to adjust the rotor speed using a cab mounted switch. The RSD the pulleys are swapped to give a different ratio.

You adjust the height of the crop deflector according to the height of the crop and then lower the whole header so that the crop gently brushes underneath the crop deflector.

The up-wards rotation of the rotor tends to kick rocks out in front rather than picking them up.

The rotating rotor mounted in the front of the header combs through the crop feeding the heads back into the keyhole area of the stripping finger where the grain is stripped from the head and thrown backwards into the header. The majority straw remains standing whilst the combine processes predominantly grain.

There is enough foreign material such as leaf and straw to enable it to feed up into the combine.

85% of the grain is threshed in the header, it will be necessary to set the combine a little differently in order to attain the normal 50 to 100% capacity increase associated with a Shelbourne header.

Since 1972, Keith Shelbourne formed Shelbourne Reynolds Engineering Ltd, designing and manufacturing farm machinery in Suffolk, England.

Read moreBy: Mike Lessiter

By: Shelbourne Reynolds

By: Shelbourne Reynolds

By: Shelbourne Reynolds

By: Shelbourne Reynolds

By: Shelbourne Reynolds