If you have questions or require advice about the Cubicle Bedder, or any of our other products, then contact us today.

Dealer Locator

Over 324 dealers world wide, contact your nearest dealer

View allThe Cubicle Bedder range is available in three models CB100, CB150 & CB300.

The robust simple design will provide a uniform bed quickly and efficiently with minimal operator effort. A wide range of materials can be spread such as sand, sawdust, wood shavings, processed paper, lime & straw and gypsum etc.

The CB100 bedder has the capacity of 0.6m³. Its compact design makes it suitable for use in restricted areas and therefore well suited for use on skid steer / mini loader

Three mounting options consist of:

| 300mm wide heavy duty conveyor belt |

| Hydraulic drive system |

| Adjustable control sides |

| Bi-Directional hydraulic belt drive |

| Chain driven agitator |

| Side protection bar |

| Hydraulic flow control valve |

The CB 150 bedder has a capacity of 1.2m³. Its large capacity in relation to its size makes it suited to restricted areas and suited for operation on a variety of machines from small tractors to handlers.

Three mounting options consist of:

| 300mm wide heavy duty conveyor belt |

| Hydraulic drive system |

| Adjustable control sides |

| Bi-Directional hydraulic belt drive |

| Chain driven agitator |

| Side protection bar |

| Hydraulic flow control valve |

The CB 300 bedder has a capacity of 1.45m³. Its large capacity is suited for large scale operations and therefore suited for use with larger handlers

Three mounting options consist of:

| 300mm wide heavy duty conveyor belt |

| Hydraulic drive system |

| Adjustable control sides |

| Bi-Directional hydraulic belt drive |

| Chain driven agitator |

| Side protection bar |

| Hydraulic flow control valve |

Heavy duty one piece belt

To achieve the ideal flow rate of the material

To prevent bridging and maintain constant feed to the belt

Simple chain drive powered via Hydraulic motor

To control the oil flow to prevent damage to the hydraulic motor on hi flow handlers

Powerful bi-directional hydraulic belt drive

Double acting oil flow to enable discharge to both sides

Bars to add protection to both the belt and bearings

Due the aggressive nature of sand etc. wearing components such as bearings can be changed quickly with minimal down time

Bolt On Handler Brackets

JCB, Manitou, Matbro, Merlo, Claas & Euro

Read more

Bolt On Handler Brackets

JCB, Manitou, Matbro, Merlo, Claas & Euro

Read more

3 point linkage brackets

This allows the use of the bedder on the front / rear using the tractor 3 point

Read more

3 point linkage brackets

This allows the use of the bedder on the front / rear using the tractor 3 point

Read more

Hydraulic 3pt tipping frame

The tipping frame allows the bucket to tip and can be self loaded from the pile.

Read more

Hydraulic 3pt tipping frame

The tipping frame allows the bucket to tip and can be self loaded from the pile.

Read more

Straw rotor

The straw rotor prevents chopped straw / line becoming bridged.

Read more

Straw rotor

The straw rotor prevents chopped straw / line becoming bridged.

Read more

If you have questions or require advice about the Cubicle Bedder, or any of our other products, then contact us today.

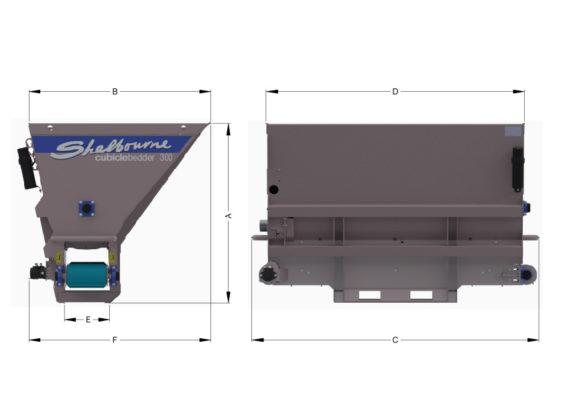

| Model | 100 | 150 | 300 |

|---|---|---|---|

| Machine Capacity | 0.6m³ | 1.2m³ | 1.45m³ |

| Overall Height (A) | 1170mm | 1390mm | 1390mm |

| Overall Depth (F) | 1235mm | 1420mm | 1420mm |

| Overall Width (C) | 1600mm | 1900mm | 2200mm |

| Tub Width (D) | 1370mm | 1670mm | 1970mm |

| Tub Depth (B) | 1150mm | 1390mm | 1390mm |

| Width of Discharge Belt (E) | 300mm | 300mm | 300mm |

| Standard Hydraulic conveyor motor | 30-35 l/min | 30-35 l/min | 30-35 l/min |

| Medium Hydraulic conveyor motor | 24-28 l/min | 24-28 l/min | 24-28 l/min |

| Low Hydraulic conveyor motor | 15-22 l/min | 15-22 l/min | 15-22 l/min |

| Min Hydraulic Oil Pressure | 125 bar | 125 bar | 125 bar |

| Max Hydraulic Oil Pressure | 180 bar | 180 bar | 180 bar |

| Optimum Hydraulic Oil Flow | 30-35 l/min | 30-35 l/min | 30-35 l/min |

| Max Hydraulic Oil Flow | 60 l/min | 60 l/min | 60 l/min |

| Weight | 440kg | 530kg | 580kg |

| Min Tractor Size | 30hp | 40hp | 50hp |

Yes, short tines can be fitted to the agitator for use with sand. Dry material will have a more even discharge rate but wet sand can be used.

It takes only a couple of minutes to adjust the gap between the metering plates in the bottom of the bucket.

Different sized hydraulic motors can be fitted to reduce the oil flow requirement to 20 litres per minute. The 150 weighs 400kg empty and so the total weight of the machine will depend upon the density of the material being used.

Looking for something specific?

Search our support area for individual model set-up guides and more...

Since 1972, Keith Shelbourne formed Shelbourne Reynolds Engineering Ltd, designing and manufacturing farm machinery in Suffolk, England.

Read moreBy: Mike Lessiter

By: Shelbourne Reynolds

By: Shelbourne Reynolds

By: Shelbourne Reynolds

By: Shelbourne Reynolds

By: Shelbourne Reynolds