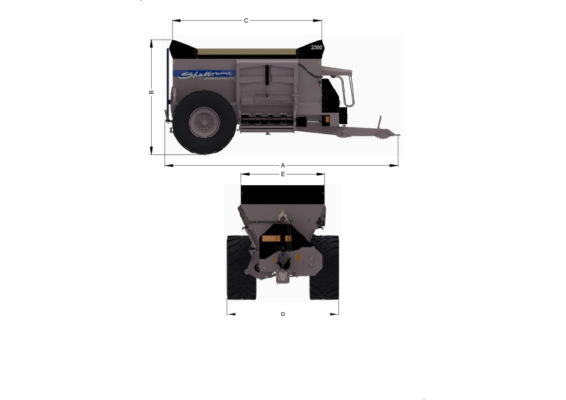

The Powerspread Pro 3200 has the capacity of 3200 gallons (14.5m³) and available in the long wheelbase format. The horsepower requirement is from 130hp.

The full length auger rotates at 13RPM and brings the material from the front and rear of the machine to the centrally mounted discharge rotor. The hydraulically operated door opens vertically which utilizes the complete width of the discharge rotor.

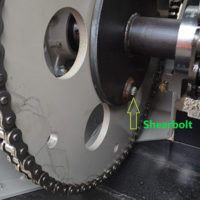

The discharge rotor works at 700 RPM in an overshot direction which allows the Hardox door to act as a shear bar to fragment the material before spreading in an arc away from the side of the machine.

The tandem axle helps reduce individual axle weights both on the road and in field. A steering rear axle can be added as on option to aid with the overall maneuverability and reduces tyre wear.