HD800 series Filter Replacements

FIL-0200a filter element (return filter located on top of the tank)

FIL-0230a filter element (pressure filter located right hand side of machine behind light board)

Gearbox

Oil grade: 75w40 fully synthetic

Quantity: 1.75lt

HD700 series filter replacements

FIL-0200a filter element (return filter located on top of the tank)

FIL-0230a filter element (Pressure filter located on trimmer A frame by right hand wheel of tractor)

Gearbox

Oil grade: 75w90 fully synthetic

Quantity: 1.75lt

600 series filter replacements

FIL-0250 Filter element (Return filter located on top of the tank under the lid)

FIL-0230a filter element (Pressure filter located on trimmer A frame by right hand wheel of tractor)

Gearbox

Oil grade: 75w90 fully synthetic

Quantity: 1.75 Lt

200 300 400 series filter replacements

Please contact your dealer stating the serial number

Gearbox

Oil grade: 75w90 fully synthetic

Quantity: 0.50lt

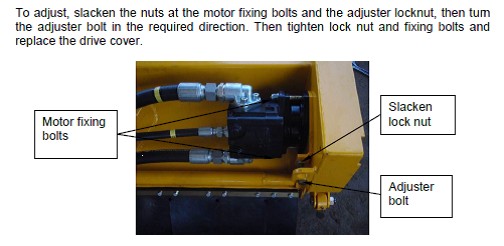

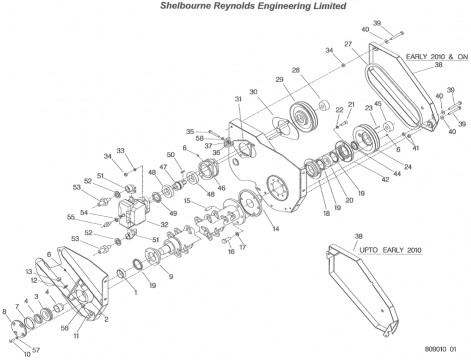

Checking the belt tension

With all our machines it is best practice to take off the drive guard and visually inspect the belt and pulleys. After many hours the pulleys can become worn. This is identified by a glazed look on the pulley and a grove in the working face which can cause the belts to slip.

The best way to check the tension is to rotate the belt towards you if the working face of the belt can be rotated more than 90deg then the belt needs more tension